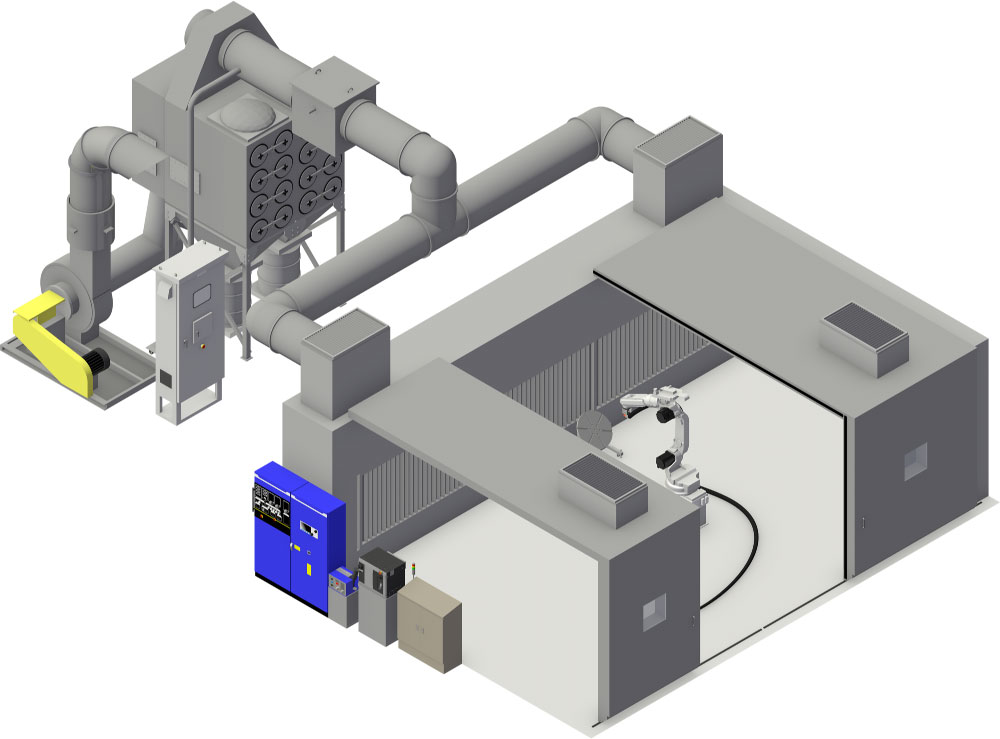

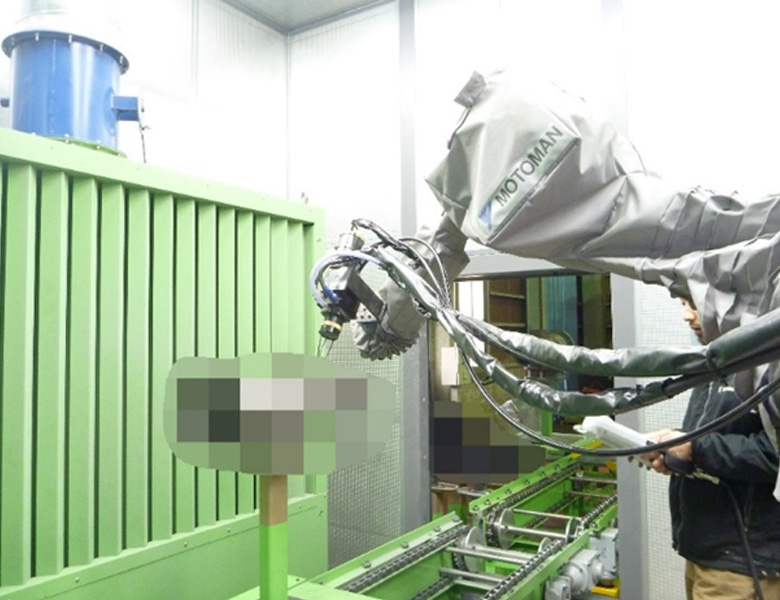

There are countless combinations of thermal spray systems, such as thermal spray methods, workpieces, robots, and ancillary systems.

However, among them, the ideal system that perfectly fits your company's production conditions is only a handful, maybe only one.

Coaken Techno provides the ideal thermal spray system based on our extensive experience and know-how.